Blog

Materializing the wools of Trás-os-Montes

One of the components of the project that gave us the most pleasure to produce was undoubtedly this showcase of samples of wool from the five breeds of indigenous sheep from Trás-os-Montes that have been processed. What is the wool of a Bragançan churra used for? What is its yarn like? How does it behave when felted or woven? This was one of the main aims of the project, to work only with the wool of local breeds and show its potential, when and if worked by hands that know, revealing and showing the community the potential of the wool that surrounds them.

The Flax long course - final day

We sowed, saw it grow, harvested, rippled, retted, dried and ground our own flax in a two and a half months time. This was the easy part of flax growing, the hardest one was yet to come and that is the one that demands us to scutch, comb and spin our flax.

Glorious flax break

This is one of the rare flax grinders still working in our country and one of the only two that work with an engine (the third I know of that is still working is powered by animal traction).

On the retting of flax (pt2)

Although without the same dedication and care that I have for photography, I make a point of making short videos along the way.

On the retting of flax (pt1)

After the harvest, comes the retting, the process by which we separate the flax fibers from the woody part of the stem, or “edge”, as it is more often called by those who traditionally work with flax.

Flax harvest at Parque da Devesa

The last few days have been intense and especially dedicated to flax, which has ripened quickly in the heat and is ready to harvest. The variety we are growing, Galego Flax, has a characteristic that is more common in wild flax and which makes it absolutely essential to harvest at the right time.

(re) building a flax scutcher

Those that know me really well know that the work I do isn't about tradition. It's about manufacturing in a more conscious and sustainable in all areas and knowing that that sustainability greatly depends on the ability of reducing production scales and using local resources.

Combing and the other side of Portuguese wool

Combing wool with Louet's mini combs has been one of my latest pleasures. And combing this gorgeous light gray portuguese merino that I brought from Ancorme a few weeks ago, makes it even more so. I don't know if you can see in the photos how the light brown shades show in the roving. It's beautiful.

HOW TO PRODUCE FLAX: Practical workshops and demonstrations at Quinta de Serralves

At Quinta de Serralves, this is the second year of cultivating a flax field with the goal of teaching about its production and processing using only locally produced fiber.

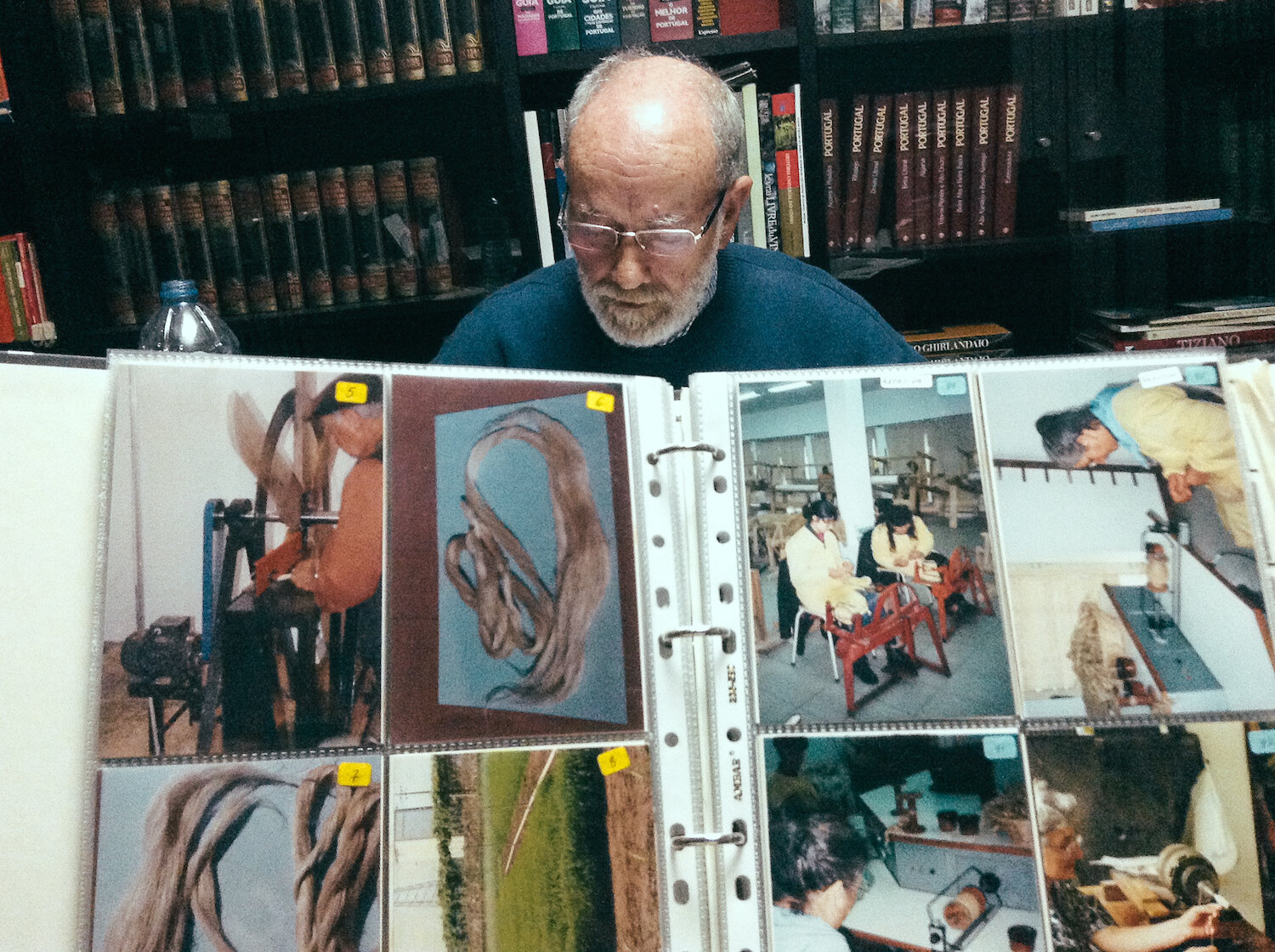

The Flax Engineer

When I went to the BPGV to pick up the Galego Flax seeds, and explained Eng. Ana Maria Barata what we intended to do and explore through this idea of growing and processing our own fibre in Serralves, she told me about this colleague of hers that worked at the seed bank years ago: at some point, he had worked in a project related to flax and had developed some equipment that we might find interesting.

Why shear?

The only purpose of shearing is not to extract wool as a raw matter, and I would even say that for most breeds kept by man, that is not even the main goal. Here in Portugal, where most sheep aren’t bred specifically for wool, and where most of the wool is no longer so valuable as it used to be, the animals are shorn anyway.

Shearing at Quinta de Serralves - 2015

Last saturday we had fabulous weather, an interested audience showed up, and after the nice shearing done by Martin, the sheep are now much lighter and we have some beautiful fleeces from the Bordaleira-de-Entre-Douro-e-Minho to work with. It was a perfect morning.

Shearing is coming!

We're almost in May and shearing season has been open for a while now, but in Serralves, the first time the Bordaleiras-Entre-Douro-e-Minho sheep will be sheared in the farm will be in the next saturday, the 9th of May, starting at 11h in the morning.

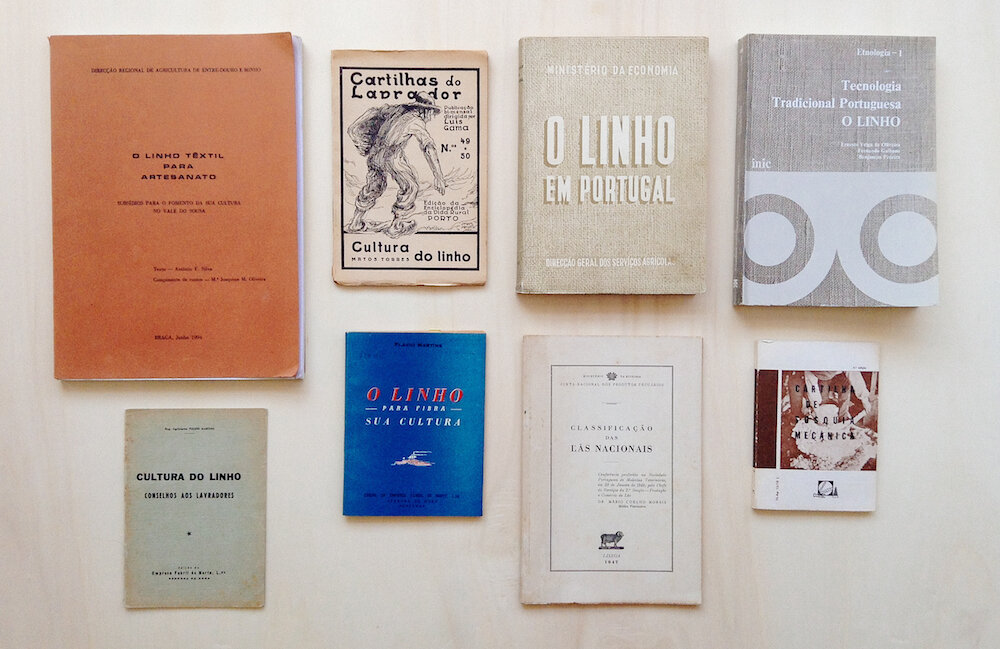

Recent acquisitions

The books I look for are always more technical and practical than historical or ethnographic, which makes them harder to find. But recently I've come across a few that have to do with topics I'm researching.

Flax. But which flax?

All cultivated flax belongs to the Linum usitatissimum L. species, of which there are hundreds of different varieties. Some of these varieties are commercial and it is these that are currently used for the commercial production of flax for various purposes, as they are more productive.

Washing wool with D. Ilídia

At the beginning of January, I went to see Mrs. Ilídia and together we washed a basin of wool, so that she could teach me how to do it properly. Washing wool is one of the seemingly simplest stages of the wool process, but for me it contains some wisdom.

The double shearing

One thing that had been confusing me was the double shearing per year. The fleece, to be sheared and used for wool needs to be at a minimum lenght, so I didn’t understand how they could shear the "meirinha" sheep twice a year.

Spinning wool with D.Benta

On one of my trips to Salto, with the purpose of visiting the Pisão de Tabuadela (The Tabuadela Wool Stomping Facilities), where the last burel blankets made by the Women of Bucos were felted, I had the chance of meeting D. Benta.

The flock of Casa da Lã

Last monday we went to see the sheep where the wool spun by the Women of Bucos come from. Over there, the women have only two terms to differentiate the wool they work with: the “lã brava” (something like wild wool) and the “lã meirinha”.

Women of Bucos

At the Casa da Lã (house of wool), the wool is still transformed through artisanal processes by a group of women that gets together every thursday to work and talk – the Women of Bucos.